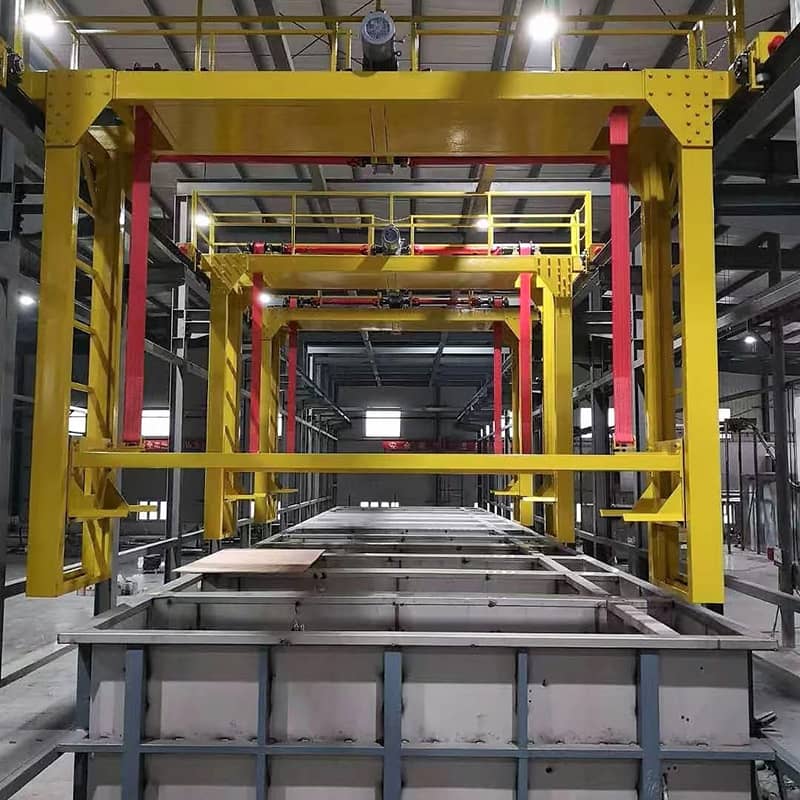

Surley bụ nchịkọta nkepretreatment na electrophoresis usoro Ụlọ ịgbasa oven usoro nnyefe bench ule ịsa ahụ teknụzụ nchekwa gburugburu ebe obibi Ngwa ngwa ebe ọrụịke niile n'otu ụlọ ahịa.

Pretreatment na electrocoating usoro

Nkọwa ngwaahịa

Ihe dị iche iche na ngwaahịa ha na usoro nhazi, njem, nchekwa, elu ya dị mfe ịmepụta ma ọ bụ

jidesie ihe ndị mba ọzọ, dị ka machining burr, oxide skin, mmanụ, wdg, ihe ndị a na-emetọ elu ga-emetụta nchikota nke mkpuchi na ike njikọ na matrix. Mkpuchi pretreatment nke mainEbumnobi bụ iji wepụ ihe ndị a bekee na-eme kwesịrị ekwesị n'elu chemical ntughari na-enye kwesịrị ekwesịCoating chọrọ nke mkpụrụ, na-amụba adhesion nke ihe nkiri, ogologo ndụ ọrụ nke ihe nkiri, Nye egwuregwu zuru ezu na-echebe mmetụta na-achọ mma mmetụta nke mkpuchi.

Ya mere, fesa ọdịnaya tupu nhazi. Ọ kachasị gụnyere akụkụ ndị a:

Ụkpụrụ ihe nkiri phosphate

Ihe nkiri phosphating nwere ike inye ntọala kwesịrị ekwesị maka mkpuchi agba, bụ n'ihi mmetụta ndị a:

1) Na-enye ebe dị ọcha, edo edo, na-enweghị griiz na-adabere na nkwụsị zuru oke

2) enhances adhesion nke organic film na mkpụrụ n'ihi anụ ahụ na kemịkalụ edinam Ọ bụghị ihe siri ike ịghọta na porous Ọdịdị nke phosphating film na-amụba elu ebe nke mkpụrụ, nke mere na njikọ ebe n'etiti abụọ na-abawanye kwekọrọ ekwekọ, na uru permeability n'etiti abụọ film n'ígwé na-eme. N'otu oge ahụ, mmekọrịta kemịkalụ dị n'etiti resin unsaturated na kristal phosphate na-emekwa ka ike jikọta ya

3) nye a kwụsiri ike na-abụghị conductive iche oyi akwa, ozugbo mkpuchi mmebi, ọ nwere ọrụ nke corrosion inhibition, karịsịa maka anode mbepụ The mbụ isi mgbe a na-eleghara anya naanị ka kpamkpam ruo mma nke mmanụ na-etolite afọ ojuju phosphating film Ya mere, phosphating film n'onwe ya bụ ihe kasị kensinammuo mmetụta nke pretreatment technology nke kasị pụrụ ịdabere a onwe ya.

Nkọwa ngwaahịa