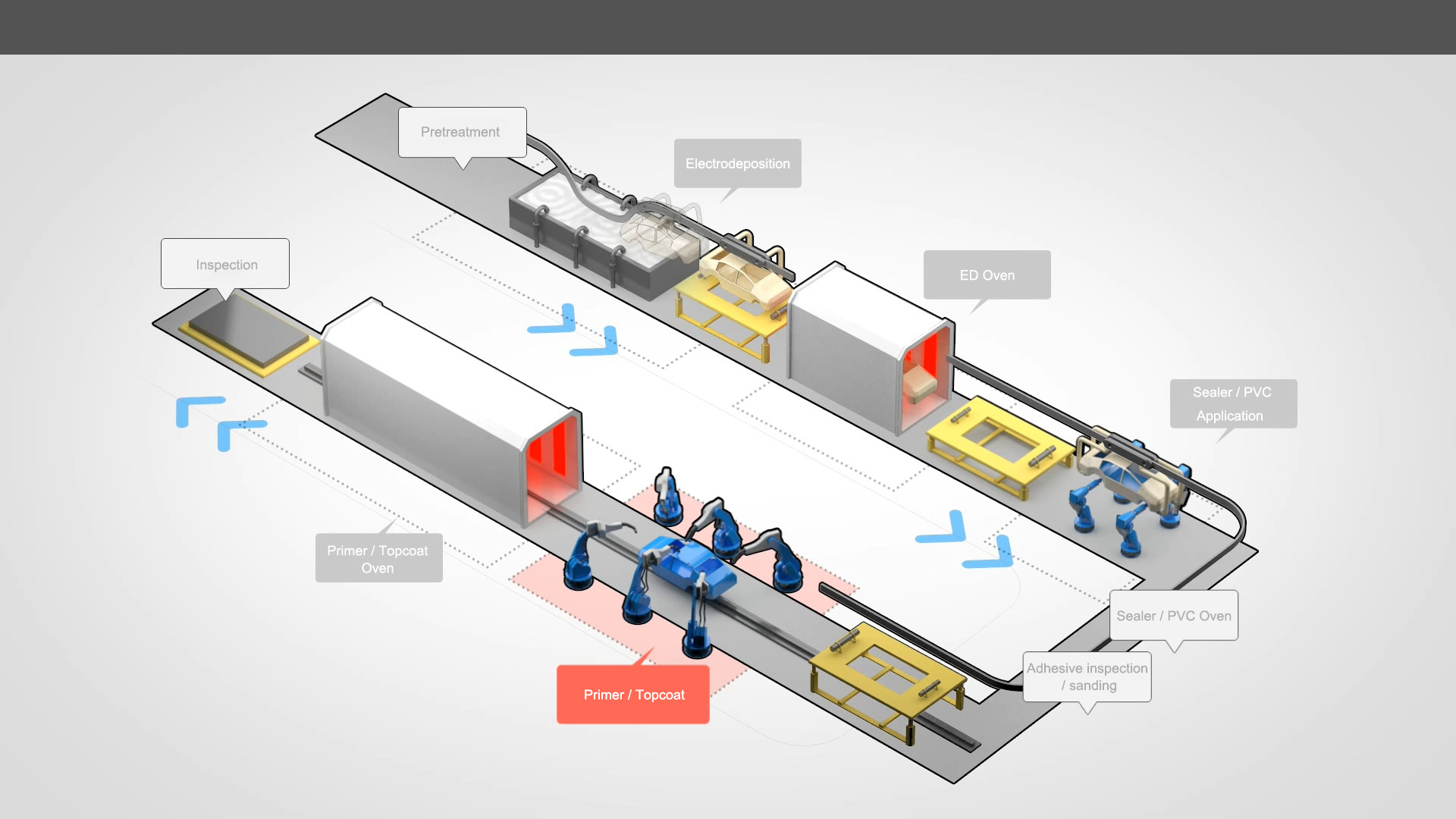

1. ọgwụgwọ mbụ: Iji wepụ mmanụ na-adịghị mkpa, ihe fọdụrụ na ịgbado ọkụ, na adịghị ọcha site n'elu ntinye ahụ ụgbọ ala site na ụlọ ọrụ ahụ, ihe nkiri zinc phosphate (3 ~ 5).㎛) na-etinye aka n'elu ahụ iji mee ka adhesion n'oge mkpuchi (electrodeposition).usoro.Maka ebumnuche nke nchebe corrosion nke ụgbọ ala.

- Tupu ihicha: Mgbe a gbakọtachara ahụ, a na-eji mmiri na-asa ya tupu e mebie ya.

- Isi mmebi: na-ewepụ mmanụ n'ime ahụ ụgbọ ala.

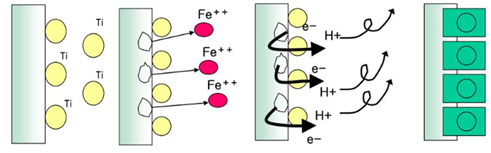

- Ntucha ọnọdụ: onye na-ahụ maka ọgwụgwọ nwere titanium dị ka ihe bụ isi, na-ekepụta ọnụ ọgụgụ buru ibu nke colloids n'elu igwe iji mee ka mmeghachi omume ahụ dịkwuo elu maka ịmepụta ihe nkiri zinc phosphate dị oke ọnụ iji mepụta kristal dị mma na nnukwu.

- Zinc phosphate film: A na-etinye ihe nkiri zinc phosphate iji mee ka adhesion nke uwe mkpuchi dị ike ma gbochie mmeghachi omume corrosion.

1) Etching na-amalite na akụkụ anode nke mpempe akwụkwọ nchara na ngwọta mkpuchi

2) Dabere na corrosion ugbu a, cations na-eri na cathode, na pH nke interface na-ebili.

3) Colloid n'elu na-aghọ a nucleus na crystallizes

- Mmiri akọrọ oven: Usoro nke iwepụ mmiri kpamkpam site na mkpụrụ mgbe emechara usoro ọgwụgwọ mbụ.

※ Mbufe ọkụ na ihicha na ihicha aka

Mgbe ikpuchi ahụ ya na ihe nkiri zinc phosphate ( ), saa ya na mmiri wee kpoo ya n'aka.Ịkpụcha aka bụ usoro iji wepụ mmiri mmiri kpamkpam na ihe a ga-ekpuchi ma na-eme usoro eserese ọzọ.Welie okpomọkụ ka ịpụpụ mmiri site na nnyefe okpomọkụ.ihicha (evaporation) bụ ihe na-eme mgbe okpomọkụ nke elu ahụ siri ike dị na kọntaktị dị ala karịa ebe a na-esi esi mmiri na ikuku ikuku dị ala karịa ike ikuku.mgbanwe agba ga-eme.Okpomọkụ na oge achọrọ maka ọkụ ihicha nke ejiri aka ịkpụ dị iche dabere na ihe, oke, na ọdịdị nke ihe a ga-ekpuchi.Na-emekarị, 10 nkeji na 120 ~ 150 ℃ bụ ihe nkịtị, na ihe mere na-ebuli okpomọkụ bụ dịkwuo uzuoku mgbali nke mmiri kwekọrọ na okpomọkụ na nkụ ngwa ngwa site na-enye ndị ọzọ okpomọkụ ike.N'oge a, e kwesịghị inwe mgbanwe ígwè ma ọ bụ kemịkal n'ihi okpomọkụ.

1,Electrodeposition usoro: Usoro nke ịmepụta ihe nkiri mkpuchi n'ime / n'èzí nke ụgbọ ala site na iji electrophoresis site na ọkụ eletrik mgbe ị na-emikpu ụgbọ ahụ na agba electrodeposition, maka nzube nke igbochi corrosion nke ahụ ụgbọ ala.

- Electrodeposition: Ihe osise Electrodeposition bụ usoro eserese nke agba na-etinye ọkụ eletrik site n'itinye ahụ ụgbọ ala n'ime ihe agba agba na anode ma ọ bụ cathode na-asọba n'ime ahụ ụgbọ ala.Otú ọ dị, ọ bụ usoro kwesịrị ekwesị maka mmepụta ihe dị ukwuu, ọ na-esikwa ike ịmegharị mgbe a na-ejikọta ihe nkiri mkpuchi na ọkụ eletrik adịghị eruba.

- DI sachaa

- Electrodeposition Drying Furnace: Maka mkpuchi cationic electrodeposition, nke a na-ejikarị eme ihe, a na-eji ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ n'ihi na ihe nkiri ahụ a na-etinye n'elu na-eme ka ọ dị mma site na ikpo ọkụ ọkụ site na mmeghachi omume nke crosslinking (thermal curing).Okpomọkụ na oge achọrọ maka ọgwụgwọ okpomọkụ dịgasị iche dabere na ihe, oke, na ọdịdị nke ihe a ga-ekpuchi.N'ihe banyere ihe mkpuchi dị ntakịrị, okpomọkụ dị n'elu bụ 200-210 Celsius C na ọkụ ọkụ na-ekpo ọkụ bụ 210-230 ° C, na oge ikpo ọkụ na-adịkarị 20-30 nkeji na ngụkọta maka nkeji 10 ma ọ bụ karịa maka okpomọkụ. oge ikpo ọkụ nke ihe a ga-ekpuchi na 200-210 ° C na-ejide oge.

- Electrodeposition polishing: Ghichaa akụkụ ahụ siri ike ma na-apụta n'elu ka ọ dị ire.

2, Halfway Paint: Nke a bụ usoro itinye agba, nke a na-akpọkarị primer.Ọ na-asachapụ elu ka uwe elu ya na-arapara nke ọma ma na-ekere òkè n'ịkwalite nguzogide corrosion.M na-eji agba dịtụ iche maka etiti dabara na agba nke uwe elu.

- Usoro etiti

- Ọkụ ọkụ ihicha ọkara

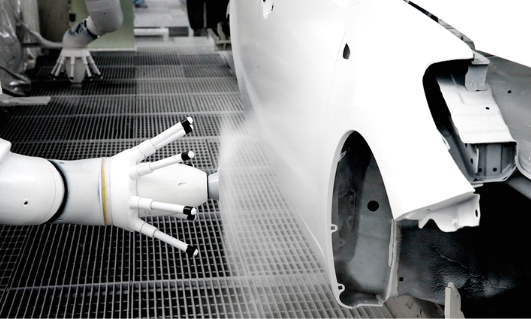

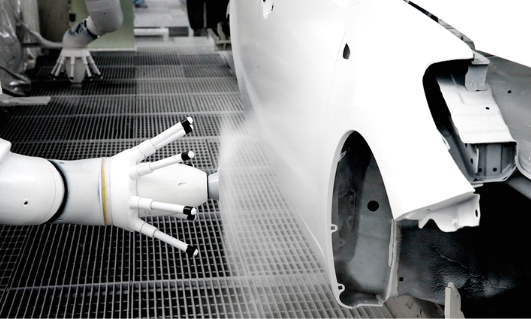

3, uwe elu: Usoro nke itinye agba ụgbọ ala a na-ahụ anya na imecha ya na agba transperent.N'oge na-adịbeghị anya, n'ihi ụkpụrụ gburugburu ebe obibi, wdg, a na-eji nwayọọ nwayọọ na-eji agba eco-friendly (ọdịnaya na-agbanwe agbanwe).Kpochapụ mgbe uwe elu gachara

- top mkpuchi usoro

- Topcoat ihicha ọkụ

※ Mbufe ọkụ na electrodeposition / etiti / elu mkpuchi kpo oku na nkụ ọkụ

N'ime ọkụ ihicha, a na-ebufe ọkụ na elu a na-ese n'ụzọ abụọ.

Convection: Ka ọ dị mfe iru okpomọkụ ọgwụgwọ okpomọkụ nke ihe nkiri mkpuchi ahụ, a na-achọ ikuku ngwa ngwa ngwa ngwa, a na-enwetakwa convection dị elu site n'ịgbasa ikuku na-ekpo ọkụ n'ime ọkụ ọkụ na-ekpo ọkụ na nnukwu ifufe (amanye convection).

Okpomọkụ na-egbuke egbuke: A na-eme ka mgbidi ahụ dị ọkụ ruo ọtụtụ narị degrees n'elu ikpo ọkụ nke ihe nkiri mkpuchi ahụ n'ime ọkụ ọkụ a na-emepụta nke ọma, na ọkụ na-ekpo ọkụ na-ebufe n'elu a na-ese n'otu ụzọ ahụ stovu na-ekpo ọkụ ahụ.

Oge nzipu: Nov-08-2022